- Dunapack Packaging

- Company

- News and Blog

- Flexographic Printing: The Modern, Sustainable Technology Behind Corrugated Packaging

Flexographic Printing: The Modern, Sustainable Technology Behind Corrugated Packaging

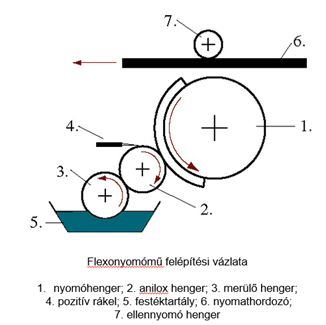

Flexographic (flexo) printing is the modern, continuously evolving version of traditional relief printing, where the printing elements are raised above the non-printing areas.

It is a direct printing process, as the printing plate (cliché) comes into direct contact with the surface of the corrugated board.

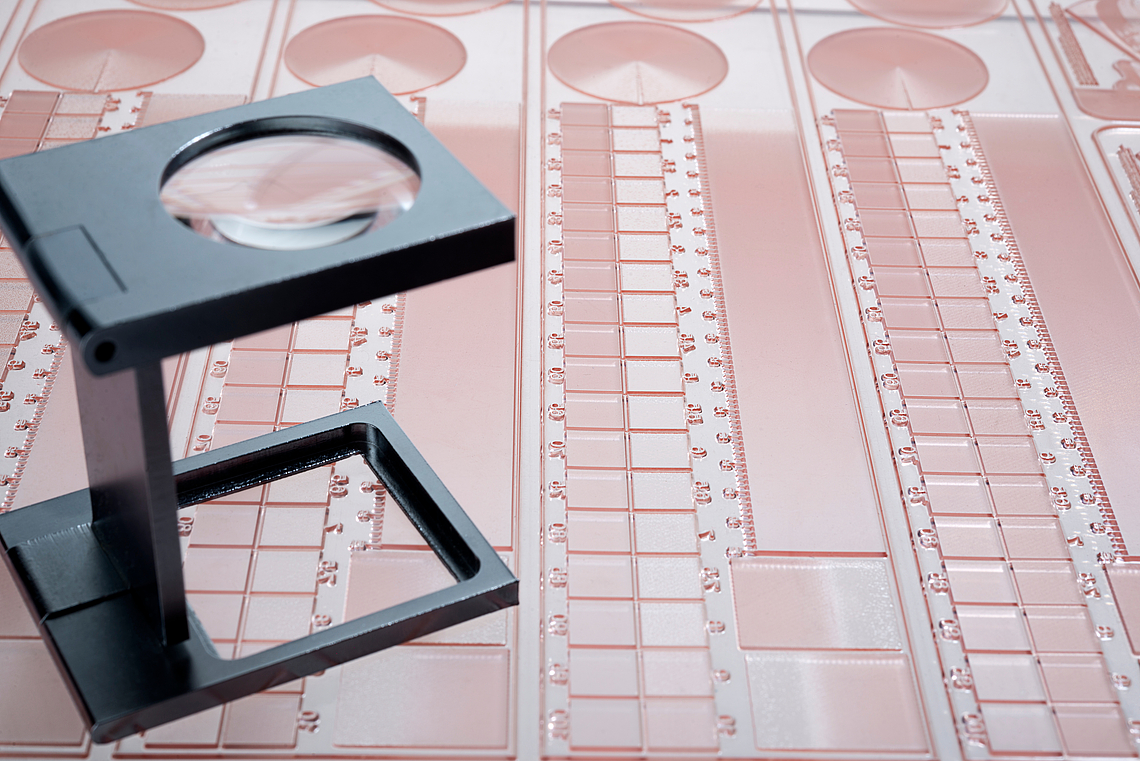

The technology uses flexible photopolymer plates that can precisely adapt to the structure and texture of the paper surface.

Ink is transferred onto the plate via a special anilox roller, while a doctor blade ensures a uniform ink film thickness. Together, these determine the color intensity and the quality of the printed image.

One of the major advantages of flexo technology is that it uses water-based inks that comply with the strictest food safety and environmental standards.

Thanks to this, flexographic printing is an ideal choice for producing sustainable packaging materials.

- Fast and efficient: Operates at very high speeds, making it ideal for large-volume packaging production.

- Versatile: Can be applied on a wide range of substrates, though it is especially prevalent in corrugated packaging.

- Environmentally friendly: Water-based inks and digital plate preparation reduce waste and lower emissions.

- High print quality: Plates used in HD Flexo technology offer significantly better performance than conventional flexo plates.

The print quality now rivals offset or gravure printing – delivering detailed, vibrant, and stable colors.

Increased screen ruling further enhances image sharpness and tonal smoothness.

Digitalization and automation now play a key role in flexographic printing as well.

New plate materials and formulations have significantly reduced the flute mark effect – a slight print distortion caused by the corrugated board’s surface structure.

Modern laser plate imaging systems ensure a more stable dot structure, resulting in more accurate color and tone reproduction.

The Flat-Top-Dots technology, in particular, provides exceptional detail and smooth gradients, especially for photo-quality prints.

HD Flexo can handle up to seven colors, making packaging not only protective but also visually distinctive.

The latest generation of machines can process various corrugated profiles (E, B, C, D, EE, EB, etc.) and can perform printing, die-cutting, gluing, and folding in a single step.

Corrugated packaging already meets the EU’s circular economy requirements.

At Dunapack Packaging, our packaging is made from up to 90% recycled paper, and the waste generated during production is reintegrated into the raw material process.

Flexo technology’s eco-friendly inks and energy-efficient machinery further reduce the ecological footprint — making the printing process not only efficient but also responsible and sustainable.

- Digital plate making: Graphic data is transferred directly onto the photopolymer plate – no film negatives required.

- Inking: The anilox roller evenly coats the plate with ink, regulated by the doctor blade.

- Printing: The plate comes into direct contact with the corrugated board, transferring the image precisely.

- Drying and coating: The drying unit allows for printing on coated board and the application of protective varnishes.

Flexographic printing enables packaging to go beyond protection — it becomes a medium of brand expression.

Thanks to ongoing technological advancements, even the smallest details, gradients, and color transitions can be reproduced with precision, while production remains fast, economical, and sustainable.

At Dunapack Packaging, we believe that innovation and responsibility together shape the future of packaging.

Flexographic technology is one of the best examples of this commitment – where quality, efficiency, and respect for the environment meet on the production line.