- Dunapack Packaging

- Company

- News and Blog

- How Is Corrugated Board Manufactured From Base Paper to Finished Sheet?

How Is Corrugated Board Manufactured From Base Paper to Finished Sheet?

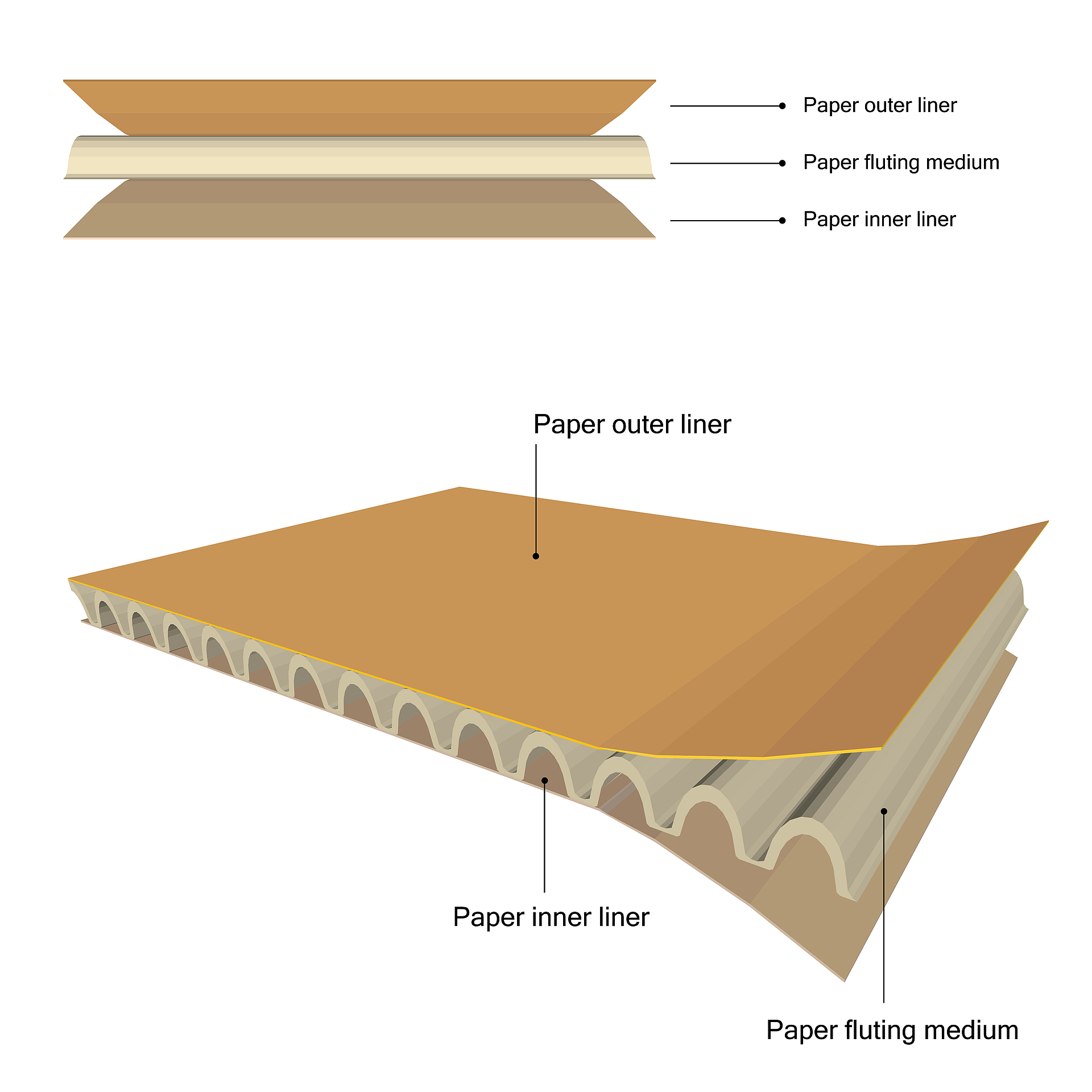

Corrugated board basically consists of two types of paper:

- Liner (facing paper)

- Fluting (corrugating medium)

1. Recycled liner papers

Testliner

A facing paper made from 100% recycled fibres, available in multiple quality grades. Since fibres may undergo up to 20 recycling cycles, starch treatment is used to ensure sufficient strength.

Schrenz

Produced from unsorted recovered paper. Typically used as a middle liner in 5-layer boards or where cost efficiency is the primary requirement.

2. Recycled fluting papers

Recycled Fluting (HBF)

A corrugating medium made from recycled fibres and treated with starch to ensure stable flute formation.

Semi-Chemical (SC)

A semi-chemical pulp-based fluting medium offering higher strength, typically used for heavy-duty packaging applications.

Why Are Base Paper Properties So Important?

The moisture content, thickness, porosity, and surface structure of base papers directly influence:

- adhesive bonding quality,

- flute formation accuracy,

- stiffness of the finished board,

- and the stability and efficiency of the production process.

Interesting Fact 1 – Why Isn’t Fresh Paper Suitable?

Freshly produced base paper should not be placed on the corrugator immediately.

During the first 10–11 days after production, the paper still behaves unpredictably:

- it may stick to the corrugating rolls,

- it can stretch and shrink unevenly,

- liners may absorb adhesive too quickly, which can lead to warping.

Therefore, base paper needs to be conditioned for at least 10 days so that its moisture content and mechanical behaviour stabilize, ensuring reliable and consistent processing.

Manufacturing begins with precise preparation of paper reels. Base papers are mounted on reel stands that ensure controlled tension and smooth unwinding — factors that already affect flute formation quality.

Preheating and Conditioning

Before entering the production line, the papers pass over preheating and conditioning cylinders.

This is not traditional drying, but rather redistribution of moisture within the paper structure to ensure:

- sufficient flexibility for corrugating,

- proper absorption of starch-based adhesive.

Corrugating takes place in the corrugator machine.

Here, the fluting paper passes between heated, toothed rolls, where:

- heat,

- pressure,

- and mechanical forming

work together to create the final flute profile.

The Most Common Flute Types

Flute dimensions are defined by international standards:

- B-flute: 2.6–3.0 mm high

- C-flute: 3.6–4.2 mm high

- E-flute: 1.4–1.7 mm high

Interesting Fact 2 – Up to 325 flutes in one meter of corrugated board!

E-flute is the finest corrugation profile, with up to 325 flutes per meter.

For comparison:

- B-flute: approx. 164 flutes/m

- C-flute: approx. 135 flutes/m

This dense flute structure provides excellent printability, high surface rigidity, and precise die-cutting performance, which is why it is often used for premium packaging applications.

A starch-based adhesive is applied to the flute tips of the corrugated medium, and the liner is pressed onto it.

Typical adhesive components include:

- starch,

- water,

- sodium hydroxide and borax (used to activate the starch).

Key Principles of Bonding

- Adhesive is applied only to flute tips.

- Bonding must occur almost instantly.

- Excess adhesive can weaken flute structure.

In single-wall board, one fluting medium is bonded between two liners.

In double-wall (five-ply) board, additional flute and liner layers increase strength for industrial and logistics applications.

Interesting Fact 3 – Starch as a “miracle adhesive”

Although it seems like a simple raw material, starch is one of the most important technological elements in corrugated board production. Corn or wheat starch is typically used for bonding, as it is a natural, renewable, and fully biodegradable material.

Advantages of starch:

- performs reliably at both low and high production speeds,

- its gelatinization temperature can be precisely controlled,

- provides a strong yet flexible bond,

- accounts for only about 2–3% of total board cost.

For these reasons, starch remains the most widely used adhesive solution in the packaging industry today.

The bonded board enters the double-backer (drying section), where heat and pressure from conveyor belts permanently set the bond between layers.

Afterwards, the board passes through:

- rotary cut-off systems,

- slitter-scorers that define sheet size and fold lines,

- cross cutters that produce finished sheets.

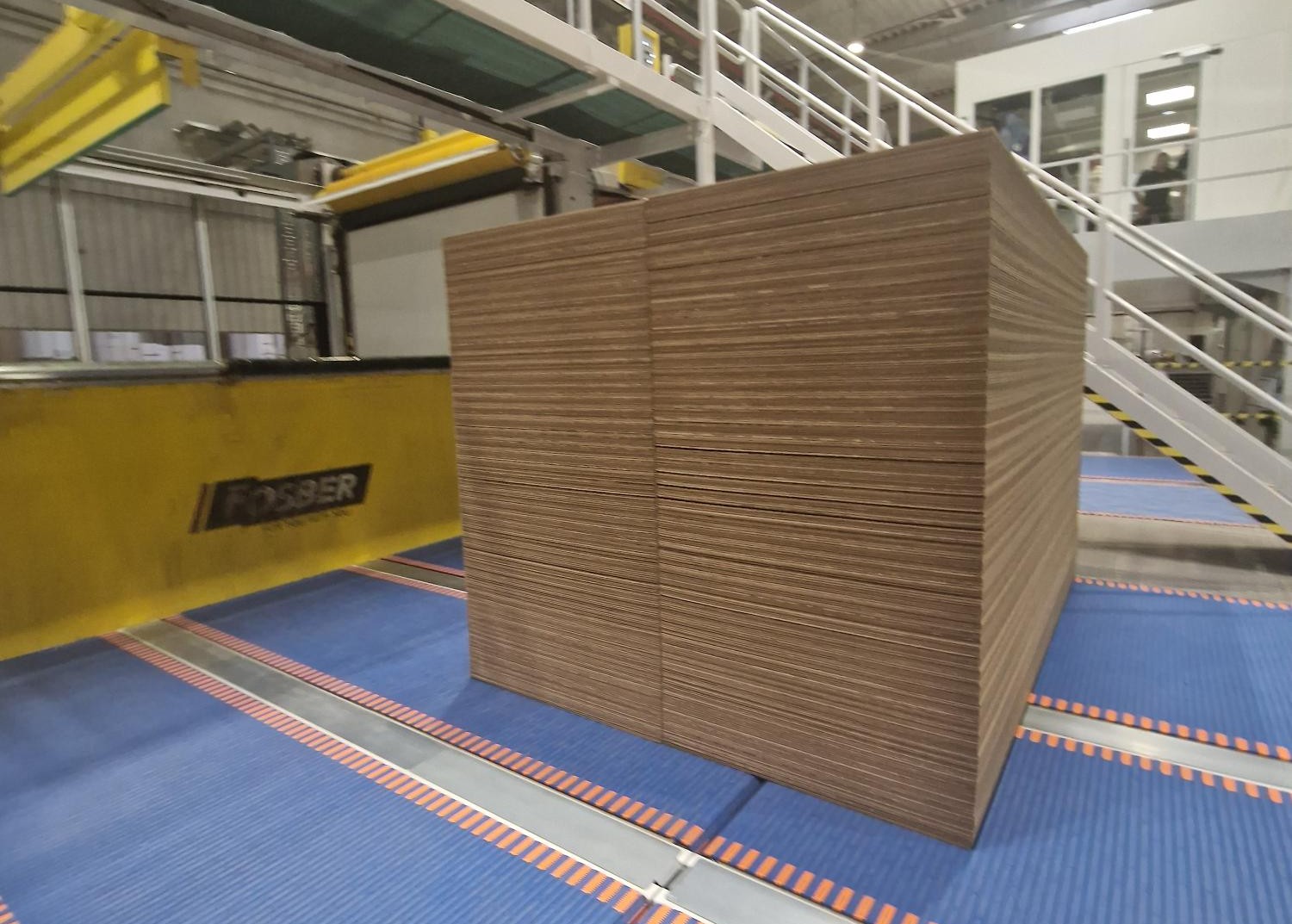

At the end of the process, stackers arrange the finished corrugated sheets into bundles.

Throughout production, continuous quality checks monitor board thickness, moisture content, and bond strength to ensure consistent product performance.

Corrugated board is the result of a precisely controlled, multi-stage manufacturing process.

Its strength comes from flute geometry, its stability from advanced bonding technology, and its sustainability from high recycled fibre content and starch-based adhesives.

For these reasons, corrugated board has become one of the most versatile, reliable, and environmentally responsible materials in modern packaging.