- Dunapack Packaging

- Company

- News and Blog

- Types of Containerboard – What You Should Know About Liners and Flutings

Types of Containerboard – What You Should Know About Liners and Flutings

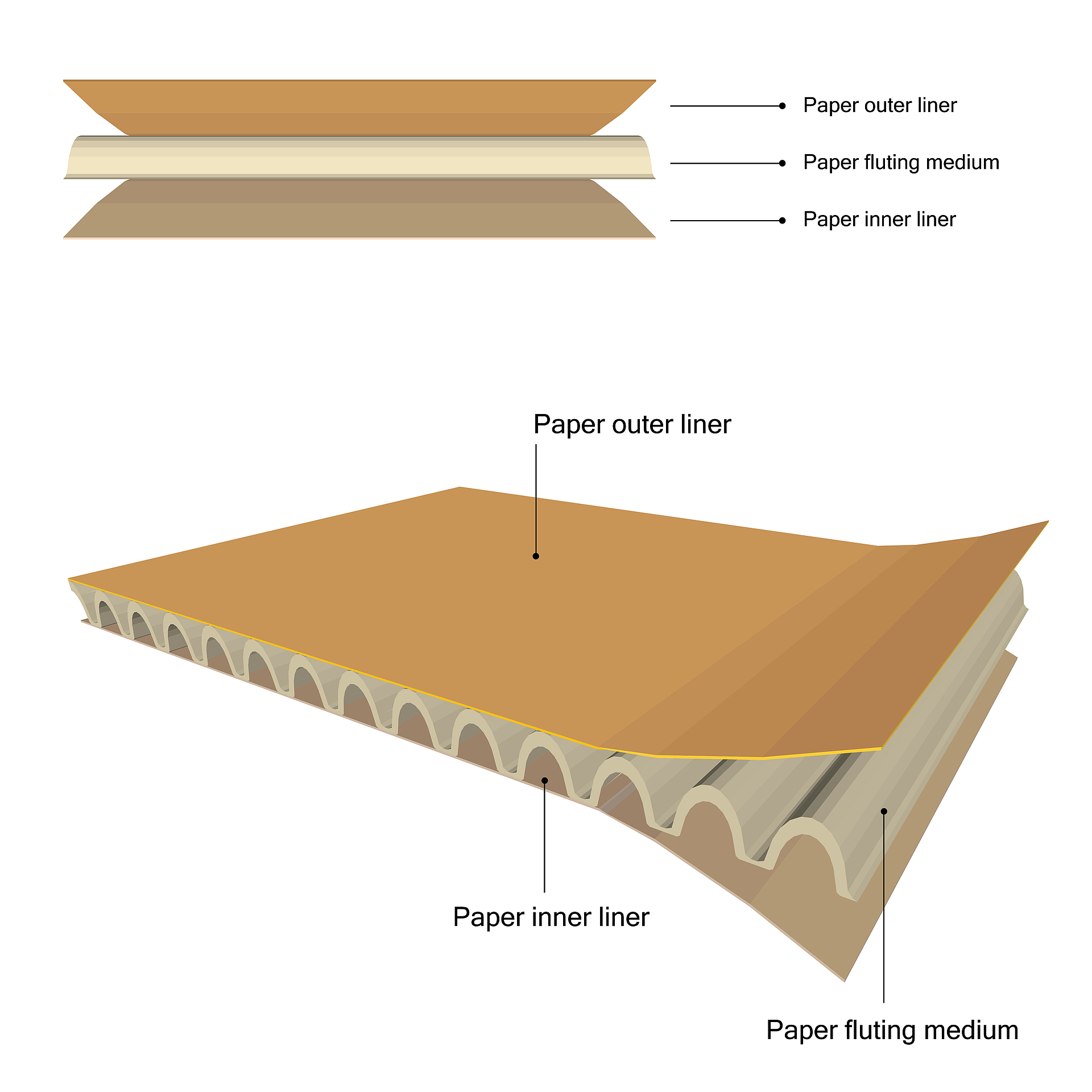

- Liners form the smooth outer and inner surfaces of the board. They determine the appearance and partially the strength of the packaging.

- Fluting is the corrugated medium between the two liners. It acts like a “paper spring”: it absorbs shocks and provides rigidity to the board.

Both components must meet different optical and strength requirements based on their function.

How is a liner made white?

There are two main methods:

1. Bleached White Kraftliner

Made from bleached fibres — a strong, printable paper produced from virgin pulp.

In two-layer white kraftliners, the top layer consists of bleached hardwood kraft fibres. The bleaching process is carried out under completely chlorine-free (TCF) conditions.

The base layer is a blend of softwood fibres and a small amount of high-quality recycled fibres sourced from corrugated board.

White testliner is also available in different quality grades.

2. Coated White Testliner (milled/coated white recycled liner)

A premium recycled-based paper with a coated surface that provides excellent printability and high visual quality.

This is also a two-layer construction: beneath the coating there is a layer of white recycled fibres, and the base layer consists of brown recycled fibres.

Coated white kraftliner is also available on the market.

Advantages and limitations

- White or coated liners:

✔ Excellent printability

✔ Aesthetic, high-quality appearance

✔ Suitable for branding and premium packaging

✘ Higher price point - Brown liners:

✔ Sustainable and cost-efficient

✔ Naturally appealing look

✘ Limited print performance

Types of liners by strength

Kraftliner

- Contains virgin fibres → very high strength and moisture resistance

- Ideal for export packaging, industrial use, heavy loads, and cold-chain packaging

Testliner

- Made from 100% selected, high-quality recycled fibre

- Excellent price–performance ratio

- Suitable for standard packaging applications

Schrenz / Srenc

- 100% recycled paper made from unselected, lower-quality recovered fibre

- Typically grey or grey-brown due to its mixed fibre content

- Uncoated, rough surface

- Commonly used as an inner liner or for low-performance applications

Fluting provides the backbone of the board: mechanical strength, rigidity, and impact resistance. Just like liners, it can be produced from virgin or recycled fibres.

Main types

SC-Fluting (Semi-Chemical Fluting)

- Made from virgin fibres

- High tensile strength and good moisture resistance

- Recommended for export packaging and heavy-duty applications

Recycled Fluting / Wellenstoff

- Made from 100% recycled fibres

- Sustainable and cost-effective

- Ideal for standard packaging needs

“Wellenstoff” is a German term commonly used for recycled corrugating medium.

Virgin fibre-based grades (kraftliner, SC-fluting)

✔ High strength

✔ Good moisture resistance

✔ Suitable for overseas export, heavy industrial goods, and sensitive products

Recycled grades (testliner, srenc, wellenstoff)

✔ Sustainable

✔ Economical

✔ Ideal for general packaging applications and normal load requirements

In Hungary, containerboard is produced exclusively by Hamburger Hungária Kft., the Dunaújváros paper mill of the Austrian family-owned Prinzhorn Group.

Their “Austro” branded products are exported at a rate of around 80%.

Their portfolio consists entirely of recycled-based grades, including:

- AustroLiner 2 and AustroLiner 3 liner papers

- AustroFluting Plus, AustroFluting-R, AustroWelle, and AustroWelle Light corrugating mediums

Available in a grammage range of 80–175 g/m².

The liner–fluting combination determines:

- the mechanical strength of the packaging

- printability and visual quality

- packaging costs

- environmental performance

Kraft-based solutions are ideal for premium and heavy-duty applications, while recycled papers offer a sustainable and cost-effective alternative for the majority of packaging needs.

You can explore the product portfolio of Hamburger Containerboard here: Products - Hamburger Containerboard